How to improve your commercial lighting costs

Rain Heads Custom Made Shipped Free Australia Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia Wide – Click Here >

Commercial Industrial Roof Vents 300mm-950mm – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

Gutter Sumps Shipped Free Australia Wide – Click Here >

Save Big Dollars by Choosing the Right Industrial Lighting

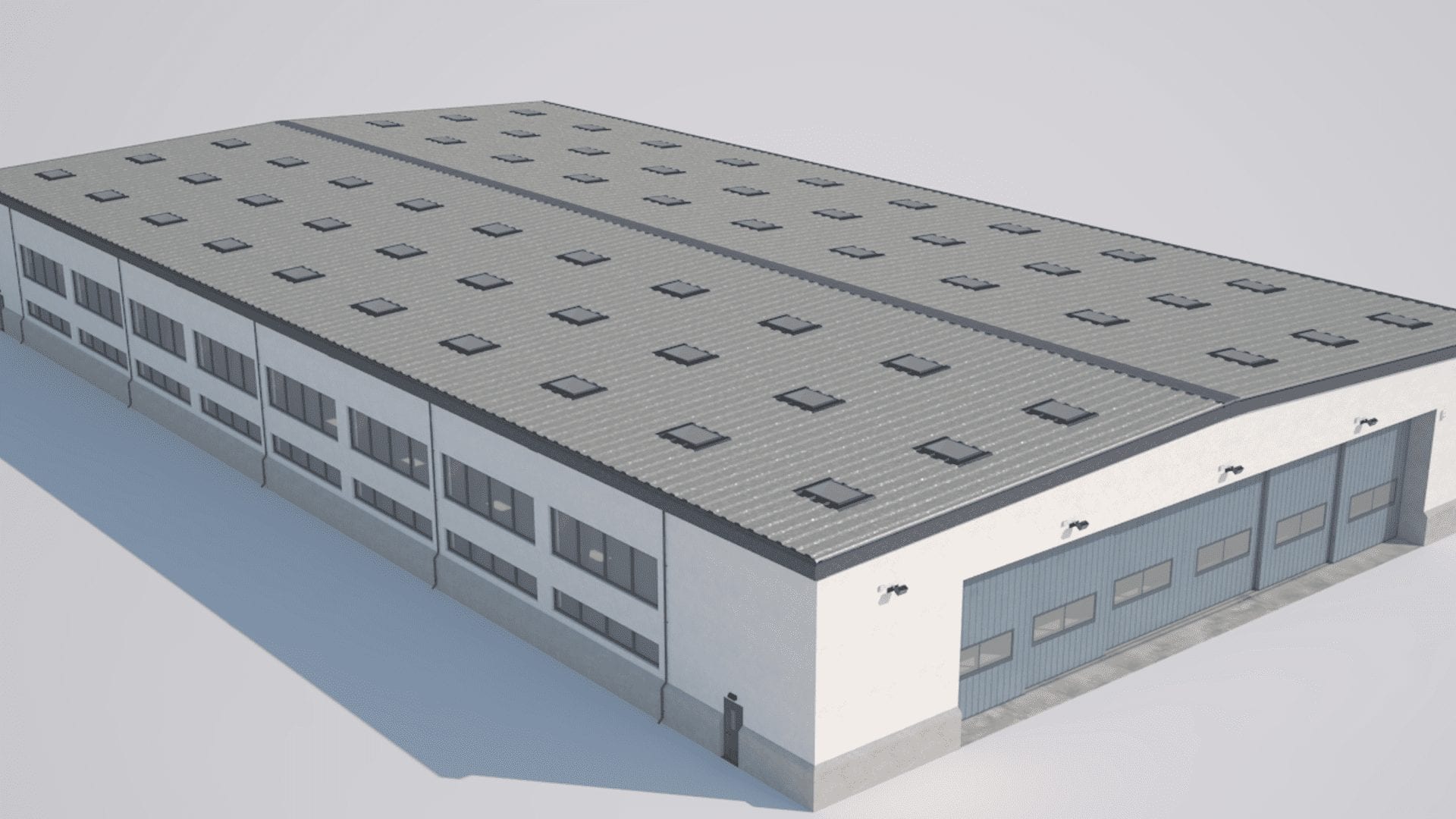

Cost is a key factor when choosing a lighting system, especially for the big facilities as warehouses and factories. Lighting is one of the biggest single consumers of electrical energy in commercial and warehouse buildings and can account for up to 80% of annual utility costs.

Choosing the Bulb:

The main options being used in factory applications are as follows:

1. Metal halides are a reliable option used in most factories. This type of lighting doesn’t require warm-up times. They offer a high-quality colour rendering. They are also the only lighting option to come close to the lumen output of the more modern LED option so far known. The drawback of this type of lighting is that most metal halides use mercury, which is less environmentally friendly than other options in the market. They also lack dimming properties, which may be a deal-breaker for some settings.

2. LEDs are easily taking over much of the territory of metal halide lights. LED’s offer the same reliability and capabilities of metal halide solutions, but with better energy efficiency, no mercury, and fewer maintenance needs. LEDs are also dimmable and operate at a lower temperature compared to metal halide. The only drawback to LEDs would be the higher costs initially when compared to fluorescent options.

3. Fluorescent continues to be a staple in the factory lighting front. These offer decent performance for the lower price. They are especially useful for aisles since they are available in tubes. However, they do not offer the same energy efficiency or lumen output as LED or metal halides. They are the lowest upfront cost of the three options, which makes them a staying power in the industry.

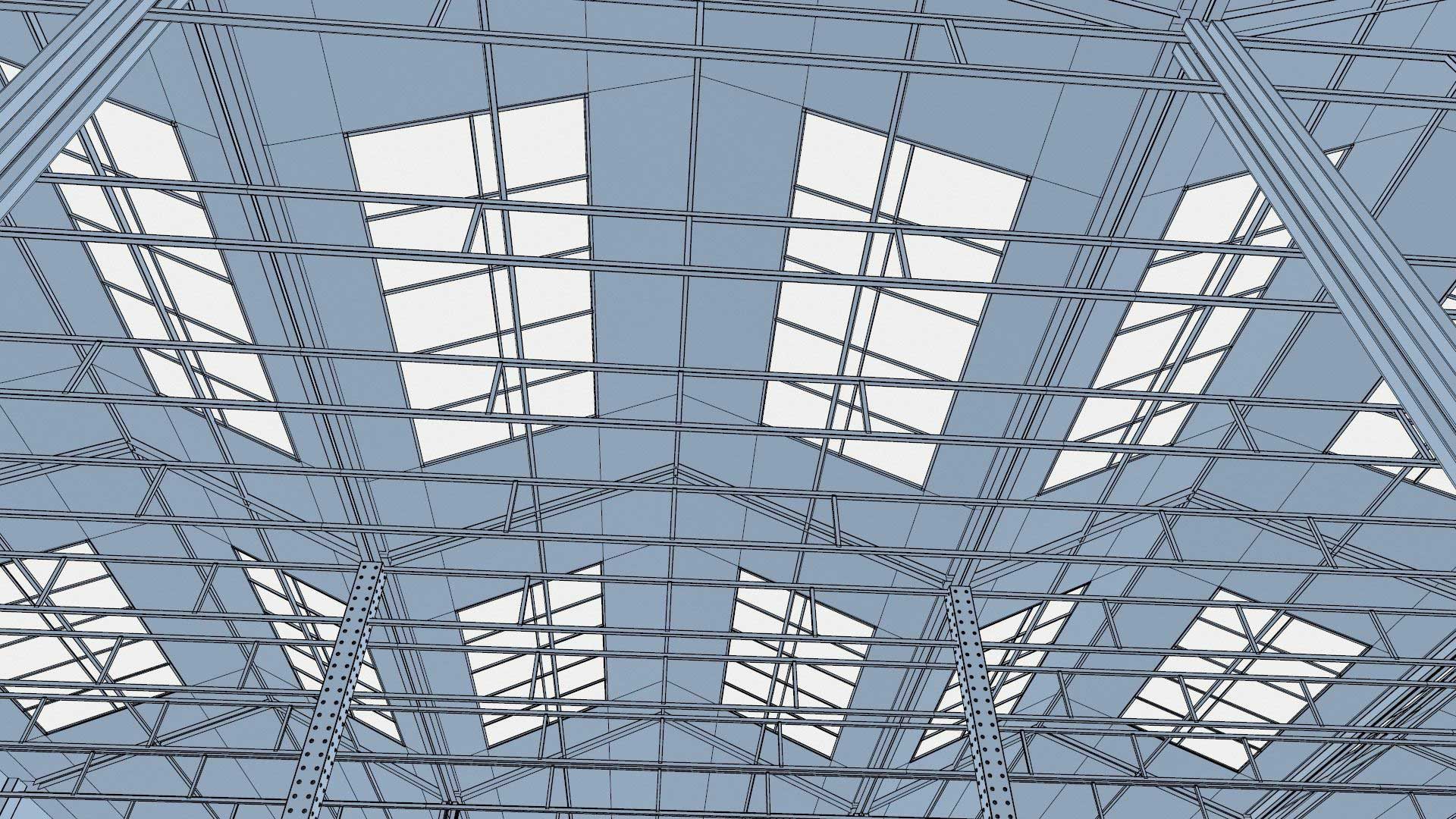

Another system of lighting, however, that the factories and warehouses need to confine themselves in is the Skylight.

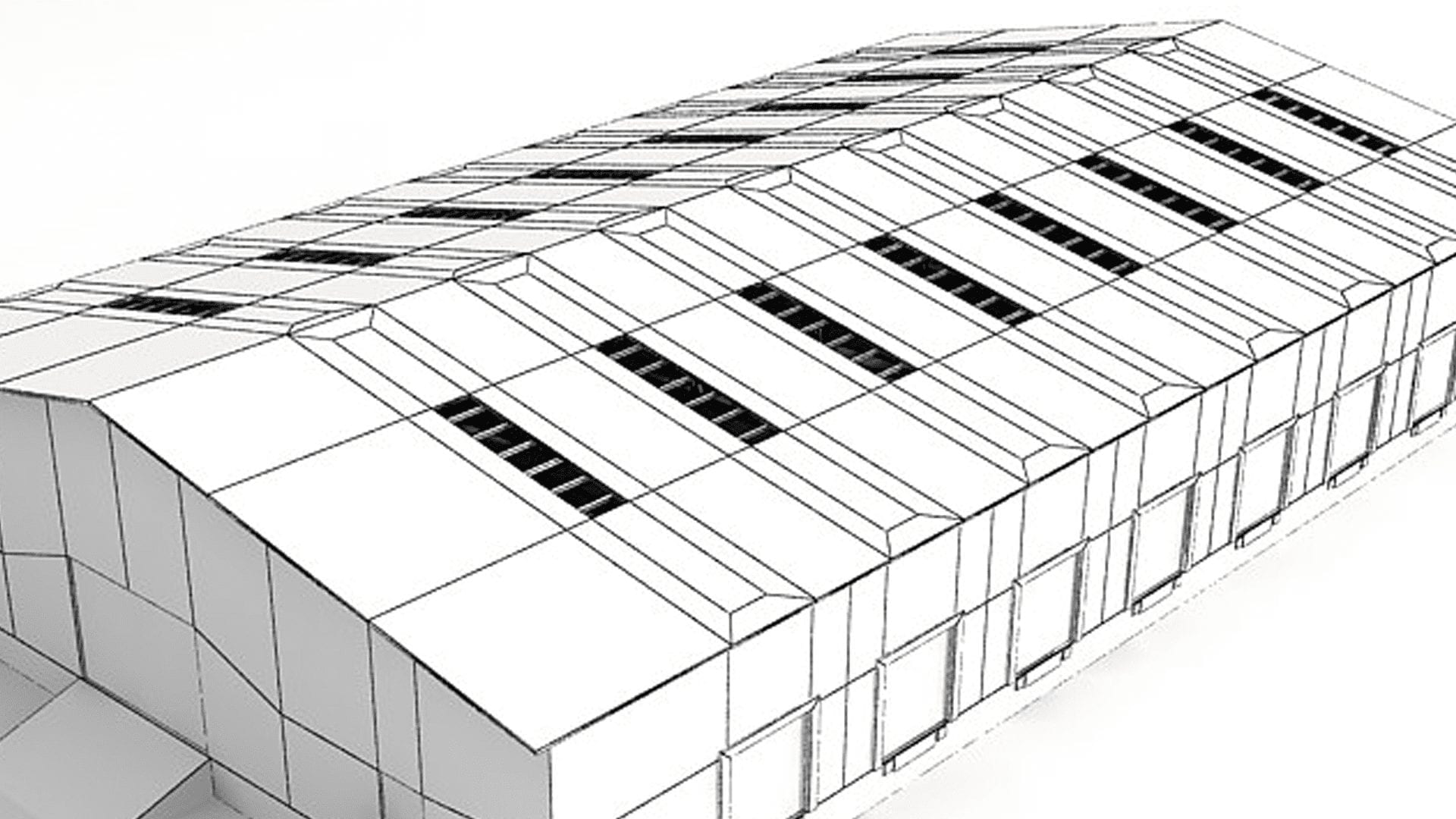

4. Skylights or clear skylight roofing panels can provide the facilities with daylighting and ventilation.

Since Skylights are located on the roof, they can easily result in unwanted summertime solar heat gain and wintertime heat loss. To improve efficiency, various technologies are used as glazing technologies to reduce these impacts, including heat-absorbing tints, insulated glazing, and low-emissivity (also known as low-e) coatings. Some manufacturers even install a translucent insulation material, such as aerogel, between the glazing layers to create a more thermally efficient assembly.

Commercial Skylight Panels: Their Operation and Use

Most homeowners install skylights to provide daylighting and/or ventilation. Recently, sun-tracking, open-sided cylinders; large lens-like elements; or mirrored reflectors mounted adjacent to a conventional skylight have been employed to provide daylighting without daytime heat gain or nighttime heat loss.

Such a skylight may be connected to a mirrored pipe or “light pipe” with a diffusing lens that mounts on or is recessed into the ceiling of the room below. Mostly, this is applied in tubular skylights. These skylight designs do not, however, provide views or ventilation.

Skylights can provide ventilation as well as light. Ventilating a building with an operable skylight help release the hot air that naturally accumulates near the ceiling. Ventilating skylights usually open outward at the bottom, and some units vent through a small, hinged panel. Such Skylights may be opened manually with a pole, chain, or crank. Automated units with electric motors or pneumatic devices are also available

Some models incorporate moisture sensors to close the Skylight when it rains automatically. Larger skylights that can be used as emergency exits are sometimes called “roof windows” and are located within a few feet of the floor.

Skylight Design Considerations

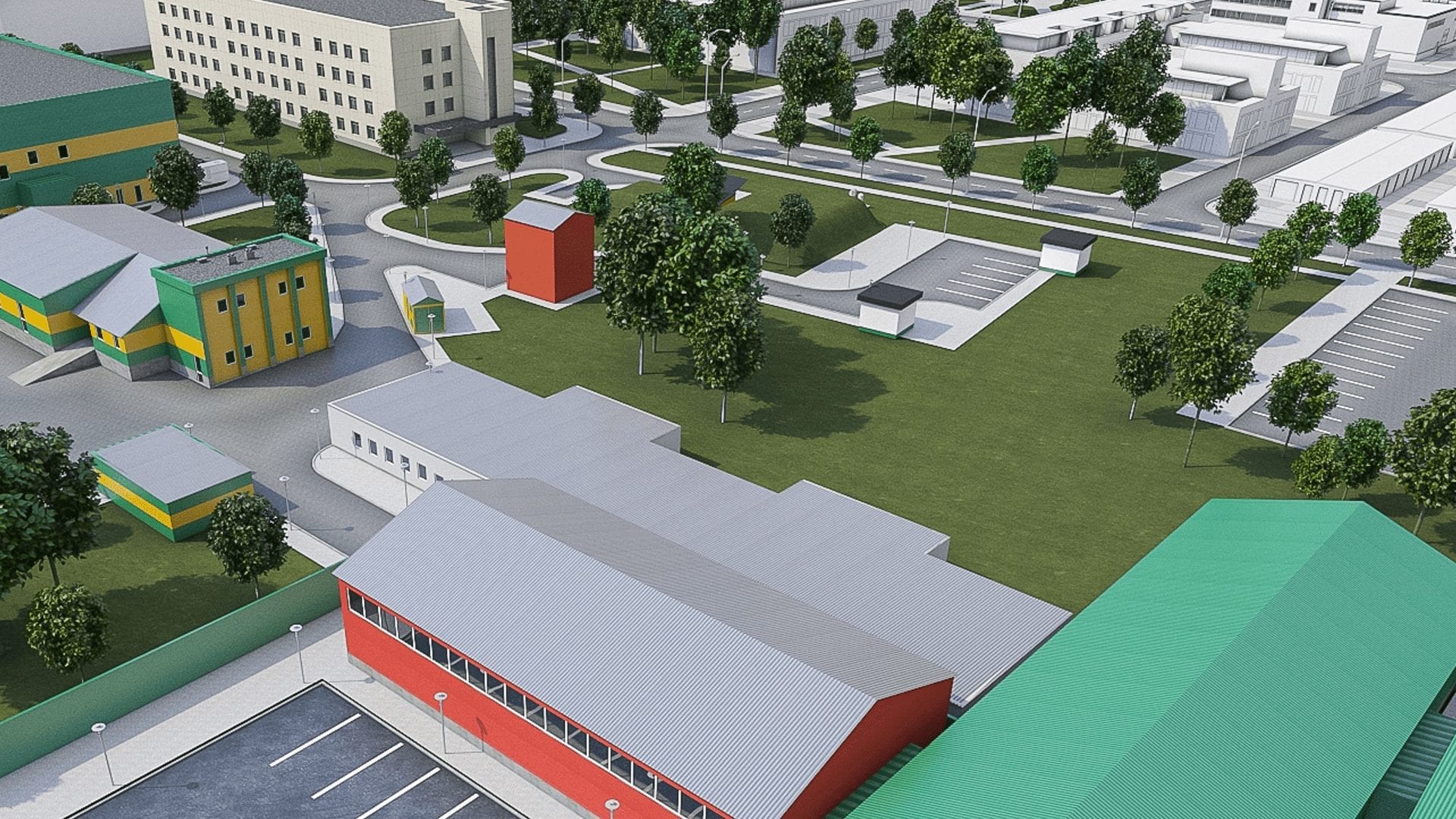

Before selecting a skylight for one’s warehouse, it’s advisable to determine what type of Skylight will work best and where to place it to optimize its contribution to your location’s daylighting and ventilation.

Selection

It’s a good idea to understand the energy performance ratings of skylights so one can select the perfect Skylight based on the local climate and design of the warehouse. For labeling energy-efficient skylights, it’s necessary so performance rating criteria by climate, based on more details, can be determined. However, these criteria don’t account for the design.

The physical size of the Skylight has great effects on the illumination level and temperature of the space below. As a rule of thumb, the skylight size should never be more than 5% of the floor area in rooms with many windows, and no more than 15% of the room’s total floor area for spaces should be with few windows.

For maximum daylighting and/or passive solar heating potential, consider a skylight’s position. Skylights on roofs that face north are known to provide fairly constant but cool illumination.

Those on east-facing roofs usually provide maximum light and solar heat gain in the morning. West-facing skylights do provide afternoon sunlight and heat gain. South-facing skylights provide the greatest potential for desirable winter passive solar heat gain than any other location but often allow unwanted heat gain in the summer. These positions of location for efficiency and improvements are to be considered accordingly.

Unwanted solar heat gain can be prevented by installing the Skylight in the shade of deciduous (leaf shedding) trees or adding a movable window covering on the inside or outside of the Skylight. Exterior shades will be more effective than interior shades when reducing heat gain in summer. Some units have special glazing that helps control solar heat gain.

Glazing

Skylight glazing is usually either plastic or glass, although other glazing technologies may be used for solar heat control. Depending on the performance expected from a skylight, different types of glazing for different skylight locations should be chosen.

Plastic glazing is usually inexpensive and less liable to break than most other glazing materials. However, plastic surfaces are prone to scratching easily, and they may become brittle and discolored over time. Many plastics also allow most of the ultraviolet (UV) rays in (unless the glazing is coated with a special film). This increases fading damage to furnishings.

Acrylics and polycarbonates are the most commonly used plastic glazing. Acrylics are weaker but less costly than polycarbonates, although polycarbonates offer high impact resistance, some yellow with age.

More expensive skylights are usually glazed with glass. Glass is more durable than plastics and does not discolor. Glass used for skylights must be “safety glazing,” which is a generic term for both tempered and laminated glass. Both keep the glass from breaking into large, sharp pieces.

Shapes

Skylights are available in a variety of shapes and sizes. The most common shapes include rectangular, circular, oval, diamond, triangular, multi-sided, and tubular.

Non-rectangular units usually use plastic glazing, as the higher quality ones use glass. The glazing can be flat, arched, domed, pyramidal, or “warped plane”—flat on the low side and concave in the section on the high side. Of these, the pyramidal, arched, and domed shapes offer flexibility for positioning. This is because their raised design allows light to enter from more extreme angles than flat or warped plane units.

The slope or curvature of the glazing also helps to shed moisture and leaves. These skylight designs do not require the additional framing needed to slope a flat skylight for proper drainage on flat or low-slope roofs.

Tubular skylights are smaller than most of the other skylights. They consist of roof-mounted light or solar collectors, increasing their daylighting potential without the need to increase their size.

Installation

Even the most energy-efficient Skylight must be properly installed to ensure that it achieves its energy performance, so it’s best to have a professional install your Skylight. In addition to following the manufacturer’s guidelines, it’s also important to consider slope and moisture control during installation. The skylight shaft also must be insulated and air sealed in the attic.

Slope

As a general rule of thumb to optimize solar heat gain in winter and minimize solar heat gain in the summer, you want to achieve a slope equal to your geographical latitude plus 5 to 15 degrees. For example, the optimum slope for a south-facing skylight in a country say at 40o north latitude, is 45o to 55o.

How Do You Choose the Best Skylights?

In order to take the confusion out of choosing a skylight, highlighting what each type of Skylight is best suited for is highly recommended. The very helpful buyer’s guide should also be provided so one can find the best skylights for themselves.

Reasons as to why Skylights remain at the top of the other lighting systems and the one to be considered.

Lighting is one of the biggest single consumers of electrical energy in commercial and warehouse buildings and can account for up to 80% of annual utility costs records. Using Skylights can reduce energy consumption by as much as 80%. This is a top way of improving the efficiency of skylights as a means of improving the lighting of a warehouse or a factory building.

Installing daylighting skylights on a warehouse or factory facility can be advantageous both environmentally and economically. Daylighting skylights aim at maximizing visual comfort in the facility and also to reduce energy use. Energy savings are achieved with daylighting skylights because they dramatically reduce the amount of artificial lighting in the facility.

The amount of money saved with reduced energy usage in the facility is worth the extra investment. Daylighting skylights are to be prismatically designed and engineered to reflect light down into a workspace or interior space, unlike the traditional skylights.

What can Solatube lighting systems offer to a warehouse project?

Controllable light levels: A Solatube Daylighting System’s natural lighting for warehouses is fully controllable with dimming capabilities that allow the level of natural lighting to be adjusted on-demand from 100 percent down to 2 percent.

Energy Saving: Using Solatube’s highly reflective daylighting devices can reduce energy consumption by as much as 80% and more.

All the benefits of natural light: In addition to the advantages of bringing abundant, high color rendering light into the workplace. Many types of daylighting designs connect the workers with the outside world, reducing or eliminating the feeling of being trapped in an artificial environment while at work. Studies have shown that natural sunlight in the workplace can increase workers’ morale and

productivity, as well as make the product sell better if the daylighting skylights are fitted.

Mood Improvement

Study after study consistently shows the same thing when it comes to exposure to natural light – an overall improvement to the mood. Not only does soaking up the sun help to increase the levels of vitamin D in the body, but it also triggers the release of serotonin. This hormone improves the connection between nerve cells in the brain and other parts of the body, thereby strongly improving the mood. This is why natural light is so important when fighting Seasonal Affective Disorder (SAD).

Increased Productivity

Just as the arrival of natural light in our bedroom gives our body the signal that it’s time to wake up, its continued presence makes sure that we know to keep on the going vigor and power throughout the day. A wide variety of academic investigations have found the same thing. The more natural light that an office space has, the more productive employees and staff become. One workplace study found that an office with no windows resulted in a 6.5% increase in sick days, while another study saw that workplaces with higher amounts of sunlight saw productivity and sales rises of between 5% to 40%.

Property Health

Natural light is not only good for the people living in a building, but it also can be highly beneficial for the structure itself. Many common varieties of mold, spores, and other unpleasant growths that can settle into walls and under tiles are repelled by natural light. This is the reason mold is most often found in darker corners, dimly lit areas, and places with little airflow. Any room with a large intake of natural light will probably find its air and walls far cleaner and fresher than a stuffier, darker space.

Skylights are an excellent addition to any property. They provide healthy natural light, a feeling of space, an airy atmosphere, and a spirit of productive energy

Fresh Air

The air in the factories is normally known to be stale and stagnant if there are not enough ways to let fresh air in. While windows, in general, are great for increased airflow, skylights are particularly useful. A skylight’s position on the upper floors of the property also means that warm air’s natural tendency to rise can be dealt with properly. When the Skylight is open, the warmer, or rather more stale air can be carried upwards and outside, allowing a fresh blast of new air to fill the room and circulate.

For the best operations, improvements, and efficiency:

Maintenance and repair tips are essential to seeing the perfect working of the skylights. Following are some of the maintenance tips:

As winter approaches, it’s a great time to inspect skylights and perform some routine maintenance. Cleaning: Like any window surface, your skylights will occasionally need to be cleaned. The best results are to be obtained when the cleaning is avoided during the hottest part of the day. From the exterior, soak the glass or plastic with mild, soapy water to loosen dirt and debris. After rinsing, a mild, non-abrasive glass cleaner is used. The glass cleaner is immediately removed with a squeegee or lint-free cloth.

Leak Check: Leaks are the most common skylight maintenance and repair issues. The checks around the drywall of Skylight are to be done for any evidence of leaks, including staining or bulging. The majority of skylight-related leaks are caused by a problem with the flashing. This is a repair best left to a professional roofing contractor.

Glass check: Skylights can crack or break from the impact of falling branches, windblown debris, or other accidents. If any cracks are noticed, this is another repair best left to an experienced roofing contractor.

Gear check: To allow for fresh air circulation, some skylights may be opened. Whether they’re operated by motor or by hand, the gears that raise and lower the Skylight can jam or fail. Now it is a good time to test the gears.

Motor test: For skylights that are out-of-reach, and motor-controlled shades are a great option. But, like any motor, skylight motors need occasional maintenance and repair. Now it is also a good time to make sure the shade’s motors are operating too.

Conclusion

Several solutions are available to light a warehouse or a factory both properly and efficiently, lowering the cost. A system that is well adapted to space will usually serve to improve work habits and the well-being of employees while reducing maintenance fees and the luminaire costs.

In many warehouses, lighting control components are often difficult to reach or maybe too far to access. Motion sensors serve to coordinate the diffusion of light based on occupancy in various areas of the warehouse or the factory. In spaces where there is no activity, there is no need to keep lights on at all times. Using motion sensors, warehouse owners can keep their energy costs down as well.