Client: Pan Civil

Work Done: Fibreglass Skylight Replacement

contact us today or call direct 1300-564-612

Pan Civil | Chillex | Hanlon | South Pacific Laundry | Show Tech | Royal Sydney Gold Club | Warehouse Re-Roofing | Strathfield Golf Club

contact us today or call direct 1300-564-612

Pan Civil | Chillex | Hanlon | South Pacific Laundry | Show Tech | Royal Sydney Gold Club | Warehouse Re-Roofing | Strathfield Golf Club

Pan Civil

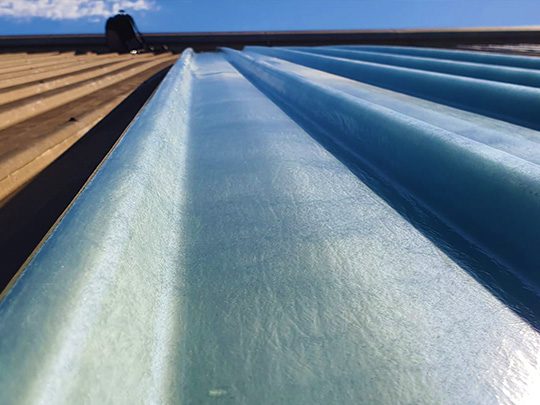

Fibreglass Skylight &

Turbine Vent Installation

Customer contacted RVA for a solution to a problem they were having with the buildup of heat and fumes from various machinery including forklifts in their commercial premises, and to suggest a way of reducing the cost of commercial lighting and to increase natural light with the use of fibreglass roof panels. The factory required the use of forklifts and machinery that produced a large amount of heat and fumes, making the working environment for their staff uncomfortable and affecting their staff morale.

RVA went out to advise what could be done to ease the conditions and to help with the reduction of power needed to light the factory. The solution that was suggested for the lighting issue was the use of Ampelite Wonderglas skylights.

Installing the skylights would not only reduce the amount of lighting needed but would also improve the feel of the environment for the staff that work there. Ampelite Wonderglas skylights also carry a 20 year Ampelite warranty.

For the heat and fumes issue, RVA suggested the use of multiple vents of varying sizes, specifically located and purposely designed for the customer.

950mm Ampelite Vents Installed

The vents were located over the upper level mezzanine to reduce heat that was getting trapped there and to increase air flow. Another key area affected by the heat was the welding bay and workshop. For this application, RVA suggested the use of 4 – 950mm ventilators with a square to round base, specifically located to remove the heat and fumes produced using the welders and heat from workshop.

The ventilators carry a 15 years warrantee and are purposely built to increase air exchange in commercial premises.

The work was completed with no interruption to the business or their commercial activities. All roof waste was removed by RVA leaving the work area clean and tidy.

The business now has a workplace that has reduced the lighting cost and often requires no lighting during the day.

It has also reduced the heat and fumes produced in their workshop and welding departments.

Also has increased the air flow over their whole factory and has increased the comfort and morale of their employees.

contact us today or call direct 1300-564-612

Pan Civil | Chillex | Hanlon | South Pacific Laundry | Show Tech | Royal Sydney Gold Club | Warehouse Re-Roofing | Strathfield Golf Club

Understanding Fibreglass Roofing for Commercial and Industrial Buildings in Australia:

A Comprehensive Guide

Fibreglass roofing sheets have gained popularity in Australia for their durability, versatility, and cost-effectiveness, particularly in commercial and industrial settings. As a professional in the construction industry, I aim to address common queries and concerns regarding fibreglass roofing, shedding light on its advantages, disadvantages, strength, longevity, and maintenance requirements.

Disadvantages of Fibreglass Roofing:

While fibreglass roofing offers numerous benefits, it’s essential to acknowledge its drawbacks. One significant disadvantage is its susceptibility to cracking and damage under extreme weather conditions, such as hailstorms or heavy impacts. Additionally, fibreglass may deteriorate over time due to UV exposure, leading to discoloration and reduced structural integrity. Moreover, improper installation or inadequate maintenance can exacerbate these issues, potentially resulting in leaks and water damage.

Strength of Fibreglass for Roofing:

Fibreglass roofing sheets vary in strength depending on their composition and manufacturing process. Generally, fibreglass reinforced with high-quality resins and additives provides sufficient strength to withstand typical loads experienced in commercial and industrial buildings. It’s crucial to consult with a qualified engineer or roofing expert to determine the appropriate fibreglass specifications based on specific project requirements and environmental factors.

Toughest Roofing Sheets:

When it comes to durability and resilience, several roofing materials stand out as top contenders. Metal roofing, particularly steel and aluminum, is renowned for its toughness and longevity, making it suitable for harsh climates and heavy-duty applications. Additionally, composite roofing materials, such as fibreglass and polycarbonate, offer excellent strength-to-weight ratios, making them ideal for various roofing projects, including commercial and industrial buildings.

Usability of Fibreglass as Roofing:

Yes, fibreglass can be effectively used as roofing material, offering numerous advantages such as lightweight construction, ease of installation, and resistance to corrosion and rot. Fibreglass roofing sheets are commonly utilized in commercial and industrial buildings due to their affordability, durability, and versatility in design and customization.

Longevity of Fibreglass Roofing:

The lifespan of fibreglass roofing largely depends on factors such as installation quality, maintenance practices, and environmental conditions. Generally, a well-installed and properly maintained fibreglass roof can last anywhere from 20 to 30 years or more. Regular inspections, timely repairs, and protective coatings can extend the lifespan of fibreglass roofing and enhance its performance over time.

Cost of Fibreglass Roofing:

Fibreglass roofing is generally more affordable compared to other roofing materials such as metal or clay tiles. While initial installation costs may vary depending on factors like roof size, complexity, and labor expenses, fibreglass roofing offers long-term cost savings due to its durability and low maintenance requirements.

Cheapest Way to Sheet a Roof:

The cheapest way to sheet a roof often involves using cost-effective materials such as asphalt shingles, corrugated metal, or fiberglass roofing sheets. However, it’s essential to consider factors like durability, longevity, and maintenance costs when evaluating the overall value and affordability of roofing options.

Fibreglass vs. Polycarbonate Roofing:

Both fibreglass and polycarbonate roofing offer unique advantages and suitability for different applications. Fibreglass roofing is known for its durability, affordability, and ease of installation, making it ideal for commercial and industrial buildings. On the other hand, polycarbonate roofing provides superior impact resistance, light transmission, and thermal insulation, making it suitable for applications requiring enhanced aesthetics and energy efficiency.

Difference between Laserlite and Suntuf:

Laserlite and Suntuf are two popular brands of polycarbonate roofing sheets, each offering unique features and benefits. While both products are designed to provide excellent durability, UV protection, and weather resistance, they may differ in terms of design, color options, and specific performance characteristics. It’s advisable to consult with a roofing expert to determine the most suitable product based on project requirements and preferences.

Maintenance of Fibreglass Roofs:

Fibreglass roofs require regular maintenance to ensure optimal performance and longevity. This includes periodic cleaning to remove debris, dirt, and organic growth, as well as inspection for signs of damage or wear. Additionally, applying protective coatings or sealants can help enhance UV resistance and waterproofing properties, thereby extending the lifespan of fibreglass roofing systems.

Conclusion:

In conclusion, fibreglass roofing offers numerous advantages for commercial and industrial buildings in Australia, including durability, affordability, and ease of installation. While it has its disadvantages and maintenance requirements, proper installation and regular upkeep can maximize its longevity and performance. By understanding the strengths and limitations of fibreglass roofing, property owners and construction professionals can make informed decisions to ensure reliable and cost-effective roofing solutions for their projects.