Harnessing the Power of Industrial Whirlybird Ventilators for Efficient Ventilation

Introduction

In the realm of industrial facilities, the importance of maintaining a comfortable and safe working environment cannot be overstated. One critical aspect of achieving this is the effective management of indoor air quality and temperature. Industrial ventilation systems play a pivotal role in ensuring that workplaces remain conducive to productivity and well-being. Among the various options available to businesses, roof exhaust fans, also known as roof turbine fans or industrial whirlybird ventilators, stand out as a cost-effective and energy-efficient solution. In this article, we’ll delve into the world of industrial ventilation, exploring the benefits of roof turbine fans, their installation, maintenance, and the importance of choosing reliable roof exhaust fan suppliers.

The Role of Industrial Ventilation Systems

Before we delve into the specifics of roof turbine fans, let’s first understand the fundamental role of industrial ventilation systems in large facilities. Industrial ventilation systems are designed to provide controlled airflow, which helps in maintaining a healthy and comfortable indoor environment. These systems serve multiple purposes:

- Temperature Control: They regulate temperature by exhausting hot air in the summer and distributing warm air in the winter, thus creating a comfortable working environment year-round.

- Air Quality Management: Industrial environments can be rife with pollutants, fumes, and dust. Proper ventilation ensures that these contaminants are removed, contributing to better indoor air quality and the health of the workforce.

- Moisture Control: Excess moisture can lead to mold growth and corrosion in industrial settings. Ventilation systems help in maintaining the right humidity levels.

- Energy Efficiency: Efficient ventilation can significantly reduce the need for heating and cooling, resulting in substantial energy savings.

Roof Turbine Fan Basics

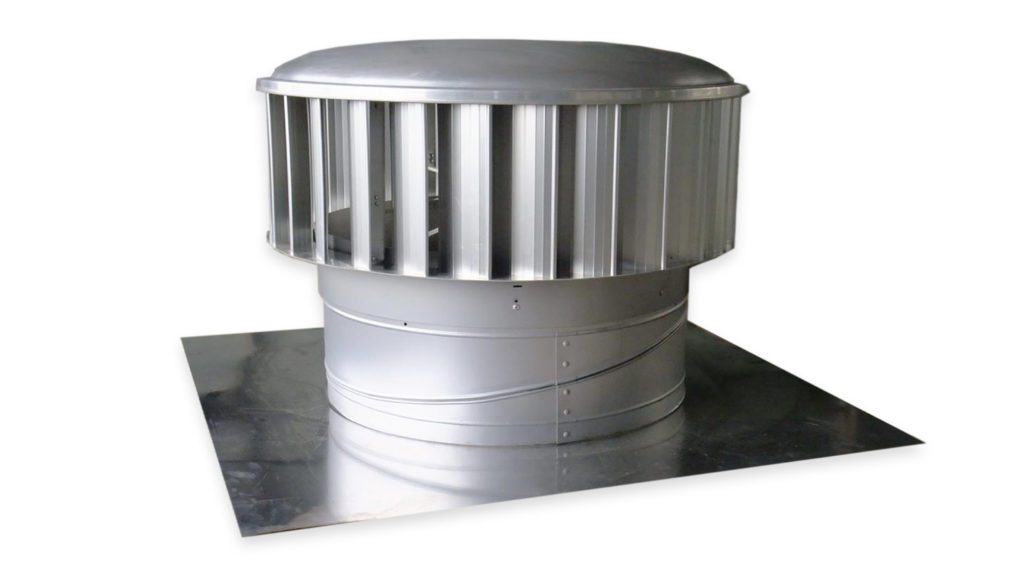

Roof turbine fans, also known as whirlybird ventilators, are an integral part of industrial ventilation systems. These devices are installed on the roof of a building and are designed to harness the natural power of wind to ventilate the interior. Here are some key benefits of using roof turbine fans:

- Energy Efficiency: Unlike electric-powered exhaust fans, roof turbine fans operate without electricity, relying solely on wind power. This makes them highly energy-efficient, reducing operational costs and carbon footprint.

- Cost-Effective: The initial cost of installing roof turbine fans is relatively low compared to other ventilation systems. They require minimal maintenance, which further reduces long-term expenses.

- Natural Ventilation: Roof turbine fans provide natural ventilation by creating a continuous flow of air, expelling hot, stale air from the building and drawing in fresh outside air. This natural airflow promotes a healthier indoor environment.

Roof Turbine Fan Installation

Proper installation of roof turbine fans is crucial to maximize their efficiency and longevity. It’s essential to hire experienced professionals for the installation process. Here are some key installation considerations:

- Location: Roof turbine fans should be strategically placed to capture the prevailing wind direction. This ensures optimal airflow and ventilation.

- Size and Number: The size and number of roof turbine fans required depend on the size and layout of the industrial facility. Consulting with roof turbine fan suppliers or ventilation experts can help determine the right configuration.

- Weatherproofing: Proper weatherproofing and sealing during installation are essential to prevent leaks and ensure the longevity of the fans.

Roof Turbine Fan Installation Warranties

When investing in roof turbine fan installation, it’s essential to inquire about warranties offered by the suppliers or installation contractors. Warranties provide peace of mind and assurance that the installed system will perform as expected. Common warranty considerations include:

- Product Warranty: Roof turbine fan suppliers often provide warranties for their products. These warranties cover manufacturing defects and ensure that the fan will function as intended.

- Installation Warranty: Installation contractors may offer warranties for their workmanship. This ensures that the installation is done correctly and that any issues arising from improper installation will be rectified.

- Maintenance Agreement: Some suppliers offer maintenance agreements that include regular inspections and servicing. These agreements can extend the lifespan of the fans and maintain their efficiency.

Roof Turbine Fan Maintenance

To ensure the continued efficiency and longevity of roof turbine fans, regular maintenance is essential. Here are some maintenance tips:

- Clean the Fans: Dust and debris can accumulate on the fan blades, hindering airflow. Regularly clean the fans to ensure optimal performance.

- Inspect for Damage: Periodically inspect the fans for any signs of damage, such as cracks or bent blades. Address any issues promptly to prevent further damage.

- Check Seals and Bearings: Inspect the seals and bearings for wear and tear. Lubricate the bearings as needed to reduce friction and maintain smooth operation.

- Monitor Performance: Keep an eye on the fan’s performance, including airflow and noise levels. Any significant changes may indicate a problem that needs attention.

Conclusion

Industrial ventilation systems are a vital component of maintaining a healthy and efficient workplace. Among the various options available, roof turbine fans or industrial whirlybird ventilators offer a cost-effective and energy-efficient solution. When considering the installation of these fans, it’s essential to work with reputable roof exhaust fan suppliers and experienced professionals for the installation process. Additionally, understanding the importance of warranties and regular maintenance is crucial to ensuring the continued efficiency and longevity of these systems. By harnessing the power of roof turbine fans, industrial facilities can create a more comfortable and productive environment for their workforce while also reducing energy consumption and operating costs.