Maximising the Efficiency of Laundry Ventilation in Australia: A Comprehensive Guide

Rain Heads Custom Made Shipped Free Australia Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia Wide – Click Here >

Commercial Industrial Roof Vents 300mm-950mm – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

Gutter Sumps Shipped Free Australia Wide – Click Here >

Introduction

Laundry ventilation is a subject that often takes a back seat when it comes to home maintenance or construction. Many people may consider it as a secondary concern, far removed from the immediate concerns of structural integrity, electrical work, or water plumbing. However, the significance of effective laundry ventilation cannot be overstated. Inefficient ventilation systems can lead to dampness, mould, and poor indoor air quality, affecting the health of the inhabitants. For those in Australia, navigating the diverse climatic conditions and local requirements for laundry ventilation can be a daunting task. This article aims to provide an educational tool to help you understand the importance of laundry ventilation, the regulatory requirements in Australia, and the options available to you, such as Turbine Roof Vents Vs. Static Vents, Fibreglass Roof Sheeting, and Stainless Steel Mini Vent installation.

Laundry Ventilation Requirements in Australia

The National Construction Code (NCC) of Australia outlines the mandatory requirements for ventilation in residential homes, including laundry areas. The code lays down specific stipulations based on the region’s climate, with variations for different states and territories. For instance, in the hot and humid conditions of Queensland, provisions for increased ventilation efficiency are necessary to tackle moisture accumulation effectively. On the contrary, the colder regions like Tasmania may require systems designed to retain heat while still providing adequate airflow.

State-Specific Guidelines

Queensland: In compliance with the Queensland Development Code MP 4.1, ‘Sustainable buildings,’ mechanical ventilation may be necessary to meet the required 10 air changes per hour for laundry spaces.

Victoria: The Victorian Building Authority emphasizes both natural and mechanical means of ventilation for maintaining indoor air quality, requiring at least 10% of the floor area of the space to be open for ventilation.

New South Wales: The NSW Planning Portal recommends complying with the AS/NZS 3000 (known commonly as the Wiring Rules) electrical installations when installing mechanical exhaust systems.

Compliance and Building Permits

It is crucial to understand that any deviation from the established state guidelines or the NCC can result in legal issues and penalties. Before undertaking any installation work, it is advisable to consult local authorities and obtain the necessary building permits.

Turbine Roof Vents Vs. Static Vents

Both turbine roof vents and static vents serve the same purpose—to enable effective ventilation. However, they differ in their operational mechanisms and efficiencies:

Turbine Roof Vents

- Efficiency: Higher efficiency due to the spinning turbine, which allows for better airflow.

- Cost: Generally more expensive than static vents but provides a quicker return on investment through energy savings.

- Noise: Generates more noise due to moving parts.

Static Vents

- Efficiency: Less efficient in comparison but works well for smaller spaces.

- Cost: Economical and easier to install.

- Noise: Almost silent as there are no moving parts.

Fibreglass Roof Sheeting Suppliers in Melbourne

Selecting the right material for your roof sheeting is essential, especially when planning to install vents. Fibreglass roof sheeting is a popular choice due to its durability and insulating properties. Several suppliers in Melbourne offer fibreglass roof sheeting, such as:

- Mulford Plastics: Located in Dandenong South, they offer a wide range of fibreglass sheeting options.

- Polycarbonate Roofing: Situated in Kilsyth South, they specialise in various fibreglass roofing solutions.

- Metal Roofing Online: Based in Carrum Downs, they provide corrugated fibreglass roof sheets at competitive prices.

Always consult with your supplier regarding the suitability of fibreglass sheeting for your specific ventilation system.

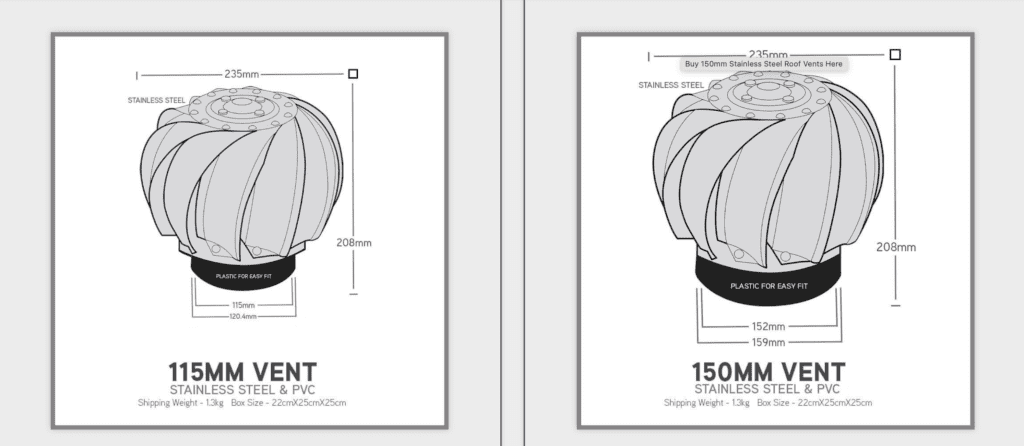

Stainless Steel Mini Vent Installation

Mini vents made from stainless steel are compact, durable and can be easily incorporated into existing laundry rooms. These are particularly beneficial for those living in coastal regions like Sydney and Gold Coast, where corrosion is a common concern due to the salt-laden air. Installation usually involves the following steps:

- Identification: Determine the best location for the mini vent.

- Drilling: Use a hole saw to create an opening.

- Mounting: Secure the vent using stainless steel screws.

- Sealing: Seal the edges with high-quality silicone to ensure no air leakage.

When selecting a mini vent, look for those that meet Australian Standard AS 1668, which focuses on the use of ventilation and air conditioning in buildings.

Conclusion

The choices you make regarding your laundry ventilation are more than just about compliance with the law; they are about creating a safe and comfortable living environment. Whether you live in humid Queensland or the cooler regions of Tasmania, understanding your state-specific requirements can go a long way in effective planning. Weighing your options between turbine roof vents and static vents, choosing the right material like fibreglass for your roofing, and installing durable and efficient mini vents can make a world of difference to your home’s air quality.

References

- National Construction Code of Australia

- Queensland Development Code MP 4.1: Link

- Victorian Building Authority: Link

- NSW Planning Portal: Link

- AS/NZS 3000 Wiring Rules: Link

- AS 1668: Link

- Mulford Plastics: Link

- Polycarbonate Roofing: Link

- Metal Roofing Online: Link

Remember, adequate laundry ventilation is not merely a regulatory obligation; it’s an investment in your well-being.