Crafting Excellence: The Art and Science of Custom Sheet Metal Roofing Products

Sheet Metal Roofing Fabrication – Contact us Now or Call Directly – 1300-564-612

Whirlybird Roof Vents Installation packages Greater Sydney Area – Click Here

Rain Heads to the Trade Shipped Free Australia Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia Wide – Click Here >

Gutter Sumps to the Trade Shipped Free Australia Wide – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

Introduction

In the realm of architecture and construction, where form meets function, the demand for customisation has never been greater. This demand extends to roofing systems, where custom sheet metal products have emerged as the epitome of design flexibility, durability, and aesthetic appeal. In this comprehensive article, we will explore the world of custom sheet metal roofing products, diving deep into custom designs, materials, manufacturing processes, and solutions that empower architects, builders, and homeowners to create roofing systems that not only protect but also inspire.

The Evolution of Custom Sheet Metal Roofing Products

For centuries, metal roofing has been cherished for its longevity and resilience. From the traditional standing seam roofs to intricate architectural marvels, metal has found its place atop structures of all kinds. However, the concept of customization has transformed the industry, allowing for roofs that are not only functional but also visually captivating.

1. Customized Roofing Designs

The heart of customization in sheet metal roofing lies in the designs. Customization offers architects and designers the freedom to dream without boundaries. Here are some aspects to consider:

1.1. Aesthetic Freedom

Customized sheet metal roofing opens up a world of aesthetic possibilities. Architects can craft roofs that seamlessly blend with the overall design of the building. Whether it’s mimicking the look of traditional shingles, replicating the beauty of natural materials like wood and slate, or creating intricate patterns and textures, the only limit is one’s imagination.

1.2. Unique Architectural Features

Customized roofing designs can incorporate unique architectural features like domes, cupolas, or skylights. These elements not only enhance the visual appeal of the building but also provide functional benefits such as improved natural lighting and ventilation.

1.3. Integration with Existing Structures

When renovating or adding extensions to existing structures, customization allows for the creation of roofing systems that seamlessly integrate with the original design, preserving the architectural integrity of the building.

2. Customized Roofing Materials

The choice of roofing material plays a crucial role in the performance and aesthetics of a building. Custom sheet metal roofing products offer an array of material options to suit diverse needs.

2.1. Aluminum

Aluminum is a popular choice due to its lightweight nature and resistance to corrosion. Customization with aluminum roofing includes a wide range of finishes and coatings to achieve the desired look and durability.

2.2. Copper

Copper roofing is celebrated for its timeless beauty and longevity. Custom copper roofing solutions can be crafted to develop a patina over time, adding character and charm to the structure.

2.3. Zinc

Zinc is another metal that develops a unique patina over time, resulting in a distinct appearance. Customized zinc roofing products can be tailored to achieve specific colors and textures.

2.4. Steel

Steel roofing offers exceptional strength and durability. Customized steel roofing systems can be designed to withstand extreme weather conditions and can be coated for enhanced protection against rust.

3. Customized Roofing Product Manufacturing

The manufacturing process of custom sheet metal roofing products is a blend of artistry and precision engineering. Here’s a glimpse into the key stages of production:

3.1. Design and Prototyping

Customization begins with the creation of detailed design blueprints. Computer-aided design (CAD) software allows for intricate detailing and accurate measurements. Prototyping may be done to ensure the design meets the desired specifications.

3.2. Material Selection

The choice of metal material is critical, as it determines the appearance, durability, and performance of the roofing product. Once selected, the metal is prepared for fabrication.

3.3. Fabrication

Fabrication involves cutting, shaping, and forming the metal sheets into the desired roofing components. Precision machinery is used to ensure consistency and accuracy in the production process.

3.4. Finishing

Finishing processes such as painting, coating, and patination are applied to the metal roofing components. This step not only enhances the appearance but also provides protection against environmental factors.

3.5. Quality Control

Stringent quality control measures are employed throughout the manufacturing process to ensure that each custom roofing product meets the highest standards of quality and craftsmanship.

4. Customized Roofing Solutions

Custom sheet metal roofing products are not limited to residential buildings. They find applications in various sectors, including commercial, industrial, and institutional. Here are some examples of customized roofing solutions:

4.1. Commercial Buildings

Commercial establishments often require roofing solutions that reflect the brand image and enhance the curb appeal of their properties. Customized metal roofing allows for the integration of logos, signage, and color schemes to achieve a cohesive look.

4.2. Historic Preservation

Preserving the architectural heritage of historic buildings often involves replicating intricate roofing designs with modern materials. Custom sheet metal roofing products can faithfully recreate the original look while offering modern durability and energy efficiency.

4.3. Eco-Friendly Roofing

Customization isn’t limited to aesthetics; it also extends to sustainability. Architects can work with manufacturers to create eco-friendly roofing solutions that incorporate features like solar panels, rainwater harvesting systems, and cool roofing materials to enhance energy efficiency and reduce environmental impact.

4.4. Industrial Facilities

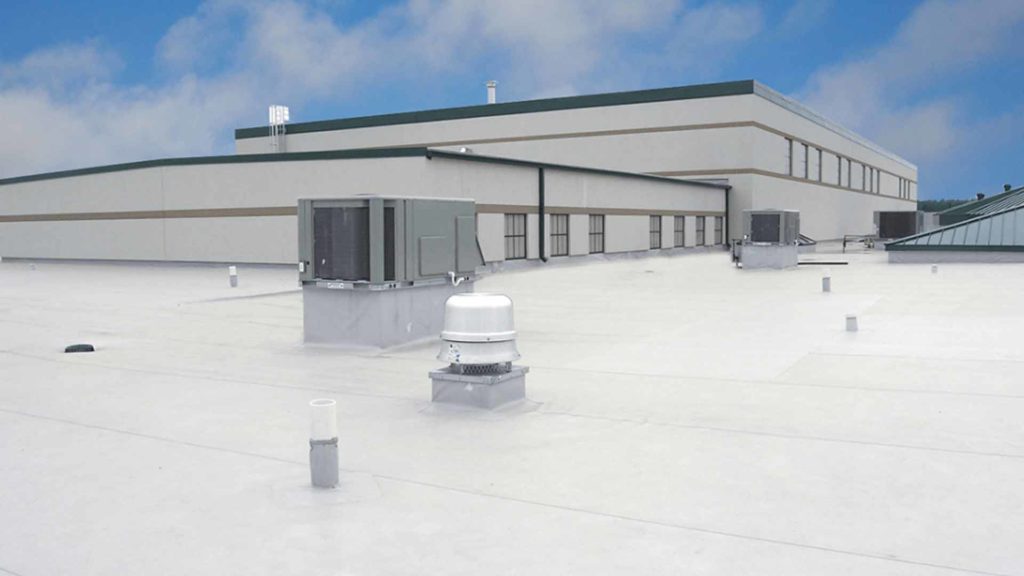

Industrial buildings often require roofing solutions that can withstand harsh environments and heavy loads. Customized metal roofing products can be engineered to meet these specific needs, providing long-lasting protection for industrial structures.

Conclusion

Custom sheet metal roofing products represent the epitome of design freedom and functionality in the world of construction. Architects, builders, and homeowners now have the tools to transform their roofing visions into reality, creating structures that not only stand the test of time but also inspire awe. As the industry continues to evolve, customization will remain a driving force behind innovation and creativity in roofing design and manufacturing. Whether it’s a historic preservation project, a modern commercial building, or a sustainable residential home, custom sheet metal roofing products are poised to shape the future of roofing solutions for generations to come.