How do I Improve The Ventilation In My Warehouse?

Rain Heads Custom Made Shipped Free Australia Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia Wide – Click Here >

Commercial Industrial Roof Vents 300mm-950mm – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

Gutter Sumps Shipped Free Australia Wide – Click Here >

Industrial Ventilation

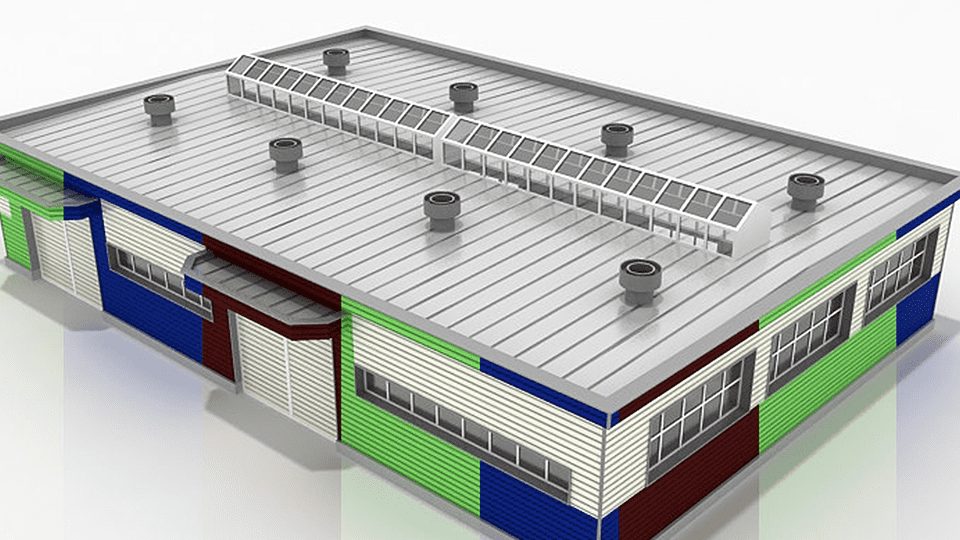

There are several things you can do to improve the ventilation in your warehouse, but they all boil down to the same basic premise; creating airflow. Having intelligently designed ways of getting air in and out of the warehouse will generate airflow, keeping the air in the building fresher, cooler, and cleaner.

So let’s look at some ways of generating that airflow.

Take Advantage of Temperature Differentials

This sounds more complicated than it is. Most people know that warm air rises, which means that the warmer air in your warehouse is on a one-way ticket to the roof. By ensuring that there is sufficient venting low down in your building to allow cooler air in, while also making sure there is plenty of venting in the roof to allow the warmer air to escape, you create a natural airflow that doesn’t require any power or active component to work.

Ultimate Dog Training System >

Granted, relying on this method alone is not the most effective way of achieving warehouse ventilation, as the airflow is not particularly fast. The hotter the air, the faster it rises, but if the air in your warehouse is hot enough to achieve a substantial amount of airflow, you have more significant problems than ventilation.

So how could we improve that airflow without cooking the inhabitants of the warehouse?

Free Tactical Knife >

Roof Turbine Vents

Rather than using passive vents (essentially just holes) in your roof, you could use something a little more active. Roof turbine vents come in a variety of flavours, and can be powered in several ways, such as electricity, or wind-powered. Regardless of how are powered, they carry out the same action, which is to spin a turbine that draws air up through the vent. This works in much the same way that vacuum cleaner does, sucking air through the vent.

This suction pulls the warmer air near the roof through at a faster rate than it would have done without the turbine vents, and that air has to be replaced in the warehouse, so the cooler air from lower down is drawn into the building at an equally fast rate.

Ultimate Dog Training System >

If you don’t like the idea of adding roof turbine vents to your electricity bill, you can get solar-powered roof turbine vents, and the ever-popular whirlybird vents, which are powered by wind.

Open Doors

It sounds too simple to be effective, but opening doors in your warehouse is a great way to create airflow, particularly if you have doors on opposite sides of the building that can be opened to create a wind-tunnel like effect. This is more effective in regions where there is generally plenty of wind.

Ultimate Dog Training System >

One thing to bear in mind if you are going to use this trick for warehouse ventilation is that the size of the door does make a difference—specifically, the relative size of the door. If, for example, you have a large roller-shutter door at one side of the warehouse, perhaps big enough to fit a delivery vehicle through, while at the other side of the building you have a regular-sized fire escape, there will be a noticeable difference. Specifically, you may find that the airflow in the area by the large door barely generates a light breeze, while the airflow around the smaller door can feel like a strong gust. This is because the same amount of air is trying to fit through a smaller space.

Free Tactical Neck Knife >

The overall effect on warehouse ventilation is unchanged—there will still be the same amount of air coming in as there is leaving. However, it may make working conditions less comfortable for anyone who is near the smaller door, as they will be continuously subjected to the stronger airflow coming through the small door.

This method also applies to windows and any other openings you can create that will let air pass through.

Install Fans

If all the various methods of generating airflow using natural means aren’t up to the task, you can always help things along by adding fans to your warehouse.

There should be some thought given to the placement and direction of these fans, however. While pointing a fan at a workbench might generate a pleasant cooling breeze for the person working at that bench, it won’t necessarily help the overall warehouse ventilation. Try to factor in the whole warehouse, and use the fans to enhance the existing airflow.

Free Tactical Knife >

Be Prepared for All Seasons

Your ventilation needs will vary from season to season. The amount of variation will depend on how different your seasons are, but as a quick example, having all the doors and windows open may be an option during the warm summers, but less so during the colder winter months.

Do not rely on just one method of warehouse ventilation, unless that method is equally as effective in all seasons, or you may find yourself struggling to keep the working conditions in your warehouse tenable during some parts of the year. One example of preparing for the different seasons might be using open doors and roof ventilation during the summer, but switching to closed doors and a heater with an intake external to the building during the winter.

Properly Extract Harmful Fumes and Particulates

If your warehouse is home to machinery or the people working in it use equipment like welders or woodworking tools, there is a good chance you will need extraction fans to carry harmful gas and substances away before they can cause harm to anyone. If you are generating airflow across the workshop, such as you might be doing with open doors or windows, and even if your airflow is all headed towards the roof, you should take extra care to make sure that any such harmful substances are being properly and safely extracted.

Free Tactical Knife >

If they are not, the very carefully planned warehouse ventilation that you have created could end up transport those dangerous gasses and particulates to other parts of the workshop, putting more of your workers at risk.

Of course, you should be adequately protecting your workers in this respect regardless of what ventilation setup you are using, but it is worth double-checking if you are going to have a robust cross-breeze blowing through the warehouse for most of the day.

Free Tactical Knife

Free Tactical Neck Knife

1 Roof Vent

Supply & Installation Price

$520/1

1 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

2 Roof Vent

Supply & Installation Price

$860/2

2 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

3 Roof Vent

Supply & Installation Price

$1,090/3

3 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

4 Roof Vent

Supply & Installation Price

$1,300/4

4 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price