What is an Upblast Exhaust Fan?

Rain Heads Custom Made Shipped Free Australia Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia Wide – Click Here >

Commercial Industrial Roof Vents 300mm-950mm – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

Gutter Sumps Shipped Free Australia Wide – Click Here >

Updraft Ventilation Systems Australia

As the name suggests, an upblast exhaust fan is a fan that pulls air upwards and expells it from the area that is being serviced by the fan. The process of expelling gas in this manner is where the “exhaust” part of the name comes from. Upblast fans are commonly used to extract the hot, moist, sometimes greasy air that is caused by cooking in a kitchen—as well as other kitchen-related activities—with more heavy-duty versions of the fan being used in commercial kitchens.

Ventilation is crucial in any building, especially in rooms like kitchens, where a range of substances are regularly cast into the air. These substances can be just irritating in some cases, or dangerous in others. Properly ventilating a kitchen not only keeps those gasses and substances out of the eyes and lungs of the people in the kitchen but also helps to keep the kitchen itself cleaner and cooler.

There are other types of ventilation for this purpose, one of the more obvious ones being downblast fans. There are advantages and disadvantages to both, and we’ll take a closer look at those shortly. But first, let’s take a closer look at what an upblast fan is, and how it works.

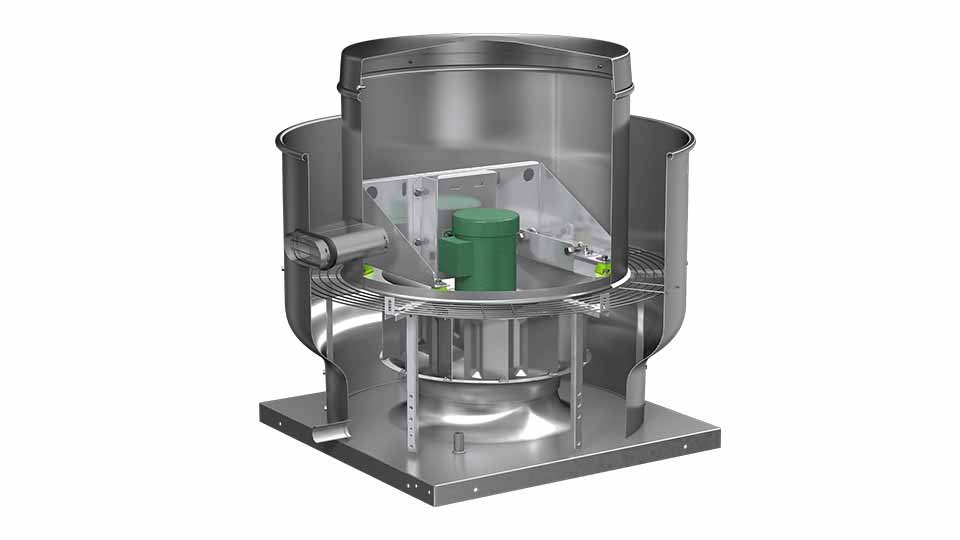

What is an Upblast Exhaust Fan and How Does it Work?

The primary purpose of an upblast exhaust fan is to pull undesirable air out of a building and move it outside. Unwanted air may include water vapour, unpleasant odours, and fumes. The fan is typically combined with a hood that is placed over the source of the fumes and odours that need removing. The hood helps to contain the undesirable air in one location, funnelling it up to the fan’s intake, where it can be more easily extracted by the upblast fan.

The fan is directly powered by a motor, with the spinning of the fan creating a kind of suction that pulls the air below up through the hood, where it can then be vented up and out of the exhaust point. This is achieved by blowing the air in the fan’s flue upwards, which creates a negative pressure in the space where the vented air was previously located. Air, as they say, loves to fill a vacuum, and the air from below then moves in to fill the void left by the vented air.

It is important to note that there needs to be sufficient ventilation coming into the room in order for this system to work at an optimum level. There is no danger of the upblast fan sucking all of the air out of the room, of course—even if the room were airtight the fan design would not be able to create such suction—but if there is not enough airflow in the room as a whole, the fan will have to work harder to achieve the same amount of extraction as it would in a room with good airflow.

Ultimate Dog Training System >

Belted or Direct Drive

Though upblast fans are more commonly driven directly by a motor, there is also the option to have the fan be belt-driven, where the motor drives a belt and the belt drives the fan. Running the fan from a belt introduces more friction into the equation, which both reduces the efficiency of the fan, but also means more maintenance since the belt will need to be periodically replaced. Belt-less fans are also easier to maintain, since cleaning them is not as tricky a task. Belt-driven fans tend to take up a little more space as well since the fan, and the motor cannot stack directly on top of each other.

There some advantages to belt-driven fans, however. For one thing, beltless fans are generally a little noisier than their belt-driven cousins. Belt-driven fans also tend to have more control when it comes to speed since the beltless fans are directly tied to the speed of the motor that is driving it.

The Exhaust

The exhaust port of an upblast exhaust fan—assuming it is installed in an upward-facing surface, like a roof, rather than a side-facing surface, like a wall—often looks a little like a big metal mushroom.

The reason for this design is to shield the flue from rain, in turn preventing the water from getting down to the fan. The domed top overhangs the top of the flue while leaving a sheltered opening for air to escape. Different setups are necessary for exhausts that exit the building horizontally, rather than vertically, but they are all designed to let the air out while preventing rain from getting in.

Free Tactical Knife >

Grease Control

One of the more significant problems of kitchen ventilation is grease. Grease has a nasty habit of getting into the air and settling on just about any surface it comes into contact with. This is obviously unpleasant from a cleanliness point of view, but it is also dangerous should the grease settle on a surface that gets walked on, or unhygienic should it settle on a surface where food is prepared.

Obviously, kitchen ventilation is there to prevent that greasy air from circulating, but what about the after the air is extracted? It is still possible for grease to cause problems outside the building, particularly if it settles on a flat roof where someone might be walking at a later date. Possibly to perform maintenance on the fan exhaust itself. Should grease get into the flues and ducts, it can also drip back down, potentially landing on an oven or some food that is being prepared. Fortunately, upblast fans have this covered. These fans are designed to capture the grease and drain it back down to an easily emptiable receptacle.

Grease is also the main reason why upblast fans are preferred for situations where there will be grease in the air. There are some downblast fans that are designed to handle the problem of grease, but many of them aren’t.

Remember, grease is not just unsightly and unhygienic; it is also a fire hazard. Failure to properly manage grease in a commercial kitchen environment can pose serious health and safety concerns.

Free Tactical Knife

Free Tactical Neck Knife

1 Roof Vent

Supply & Installation Price

$520/1

1 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

2 Roof Vent

Supply & Installation Price

$860/2

2 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

3 Roof Vent

Supply & Installation Price

$1,090/3

3 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

4 Roof Vent

Supply & Installation Price

$1,300/4

4 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price