Customization and Craftsmanship in Sheet Metal Roofing Products

Sheet Metal Roofing Fabrication – Contact us Now or Call Directly – 1300-564-612

Whirlybird Roof Vents Installation packages Greater Sydney Area – Click Here

Rain Heads to the Trade Shipped Free Australia Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia Wide – Click Here >

Gutter Sumps to the Trade Shipped Free Australia Wide – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

When it comes to roofing, one size does not fit all. The roofing material you choose plays a pivotal role in the longevity and performance of your roof. Today, more than ever, homeowners and builders are seeking customisation and craftsmanship in roofing materials to ensure they get the best fit for their unique needs. In this comprehensive guide, we will delve into the world of roofing material customisation, roofing product craftsmanship, and the intricate processes involved in sheet metal roofing fabrication.

Introduction to Roofing Material Customization

The roofing industry has witnessed significant advancements in recent years, offering consumers a wide range of options for their roofing needs. Customization has become a buzzword in the industry, allowing homeowners and builders to tailor their roofing materials to match their specific requirements.

Roofing Material Customization Benefits

- Enhanced Aesthetics: Customized roofing materials enable homeowners to choose the colors, patterns, and textures that best complement their architectural style.

- Improved Performance: Customized roofing materials can be designed to withstand the specific climatic conditions of a region, ensuring long-term durability.

- Energy Efficiency: Customized roofing can incorporate energy-efficient features such as reflective coatings or solar panels to reduce energy consumption.

- Cost-Effectiveness: Tailored roofing materials can optimize material usage, reducing waste and lowering costs.

The Art of Roofing Product Craftsmanship

Craftsmanship in roofing products involves meticulous attention to detail and the use of high-quality materials to create roofing solutions that not only perform well but also enhance the overall aesthetics of a structure.

The Role of Craftsmanship in Roofing

- Precision Fabrication: Craftsmanship ensures that roofing materials are fabricated with precision, minimizing installation issues and ensuring a tight fit.

- Attention to Detail: Craftsmen pay close attention to the finer details of roofing products, ensuring that they meet the highest standards of quality.

- Durability: Craftsmanship results in roofing materials that are built to last, reducing the need for frequent repairs or replacements.

Roofing Product Customization and Craftsmanship

Combining customization with craftsmanship allows homeowners and builders to achieve roofing solutions that are both functional and aesthetically pleasing. Craftsmen can work with clients to design and create roofing materials that meet their exact specifications.

The Roofing Product Design Process

The design process is a crucial step in roofing material customization. It involves creating roofing materials that are not only visually appealing but also highly functional.

Key Considerations in Roofing Product Design

- Architectural Compatibility: The roofing material should complement the architectural style of the building.

- Climate Adaptability: Designers must consider the local climate to ensure that the roofing material can withstand extreme weather conditions.

- Energy Efficiency: Incorporating energy-efficient features into the design can reduce heating and cooling costs.

- Environmental Impact: Sustainable roofing design can minimize environmental impact by using eco-friendly materials and recycling options.

The Roofing Product Manufacturing Process

The manufacturing of roofing products is a complex and highly specialized process. It involves various stages, each contributing to the final quality and performance of the material.

Steps in Roofing Product Manufacturing

- Material Selection: The choice of base materials, such as sheet metal, is critical in determining the strength and durability of the roofing product.

- Cutting and Shaping: Precision cutting and shaping machines are used to create roofing panels or components with the desired dimensions.

- Coating and Finish: Depending on the design, roofing materials may undergo treatments like painting, galvanizing, or applying reflective coatings.

- Quality Control: Rigorous quality control checks are conducted at multiple stages to ensure that the roofing materials meet industry standards.

- Customization: Customized features, such as color or pattern, are incorporated during the manufacturing process.

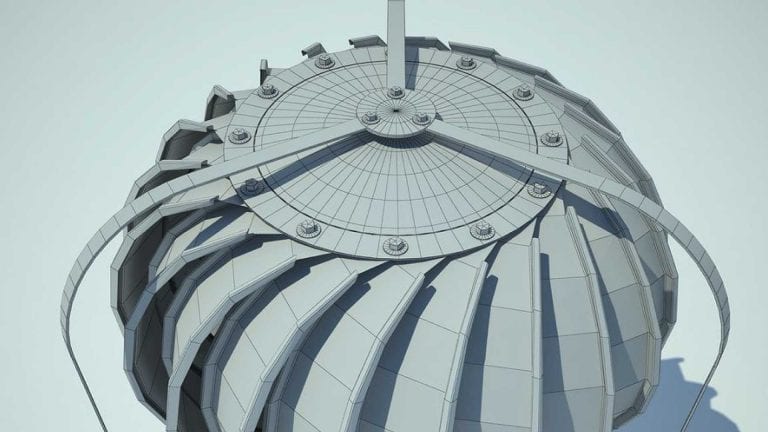

Advanced Sheet Metal Roofing Fabrication

Sheet metal roofing is a popular choice for its durability and flexibility in design. It offers numerous customization options, making it an ideal choice for those looking for roofing material tailor-made to their preferences.

Sheet Metal Roofing Design

- Material Thickness: The thickness of the sheet metal can be adjusted based on the expected loads and weather conditions.

- Profiles and Shapes: Sheet metal can be cut and shaped into various profiles and shapes, allowing for intricate designs.

- Surface Finish: Different surface finishes, such as matte, glossy, or textured, can be applied to enhance aesthetics.

Sheet Metal Roofing Fabrication Techniques

- Bending and Forming: Precision bending machines are used to create the desired curves and shapes in sheet metal roofing.

- Seam Locking: Seam locking is a critical technique to ensure watertight connections between sheet metal panels.

- Fastening: Proper fastening methods are essential to secure sheet metal roofing and prevent wind damage.

Benefits of Sheet Metal Roofing

Sheet metal roofing is highly customizable and offers a plethora of benefits, making it a preferred choice for many:

- Durability: Sheet metal roofing is known for its long lifespan, often lasting 50 years or more.

- Customization: The material can be tailored to suit various architectural styles and design preferences.

- Low Maintenance: Sheet metal roofing requires minimal maintenance, reducing long-term costs.

- Energy Efficiency: Reflective coatings can be applied to sheet metal roofing to increase energy efficiency.

The Role of Sheet Metal Fabrication Services

Sheet metal roofing customization and craftsmanship often require the expertise of specialized fabrication services. These services play a crucial role in turning design concepts into tangible roofing products.

Services Offered by Sheet Metal Fabrication Shops

- Custom Design: Fabrication shops work closely with clients to translate their design ideas into practical roofing solutions.

- Precision Cutting: High-precision cutting equipment ensures that sheet metal components meet exact specifications.

- Welding and Joining: Welding and joining processes are used to create seamless connections between sheet metal pieces.

- Quality Assurance: Fabrication shops conduct rigorous quality checks to ensure that the final product meets industry standards.

Technological Advancements in Sheet Metal Fabrication

Technological innovations have transformed sheet metal fabrication, making it more efficient and precise:

- Computer Numerical Control (CNC) Machines: CNC machines offer precise and automated cutting, shaping, and forming of sheet metal.

- 3D Printing: 3D printing allows for intricate and complex designs in sheet metal roofing components.

- Digital Prototyping: Digital prototyping tools help in simulating and optimizing designs before fabrication begins.

Conclusion

Roofing material customization and craftsmanship have become essential elements in the roofing industry. The ability to tailor roofing materials to meet specific design, performance, and aesthetic requirements provides homeowners and builders with greater flexibility and choice.

Sheet metal roofing, with its versatility and customisation options, exemplifies the synergy between customization and craftsmanship. When coupled with advanced fabrication services and technology, sheet metal roofing products can truly be works of art, offering both functionality and beauty.

As the roofing industry continues to evolve, it is crucial for consumers to stay informed about the latest advancements in roofing material customisation and fabrication. Whether you are building a new home or renovating an existing one, the combination of customisation and craftsmanship in roofing materials can enhance the value and performance of your property while contributing to its unique aesthetic appeal.