What Are the Pros and Cons of a Metal Roof?

Rain Heads Custom Made Shipped Free Australia Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia Wide – Click Here >

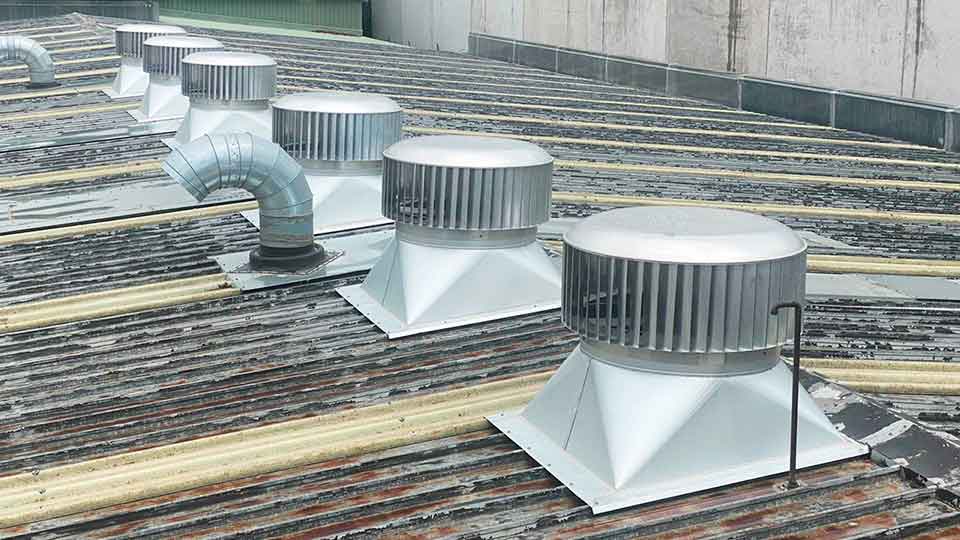

Commercial Industrial Roof Vents 300mm-950mm – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

Gutter Sumps Shipped Free Australia Wide – Click Here >

Why Metal Roofing?

Choosing a roofing style for a new build or the renovation of an old build can be a real headache, given all of the choices there are. Metal roofing compounds this headache by representing a multitude of different options by itself, both in style and material.

Fortunately, we’re here to lay out everything you need to know about metal roofing, so you can make an educated decision on whether metal roofing is right for you.

What are the Metal Roof Choices?

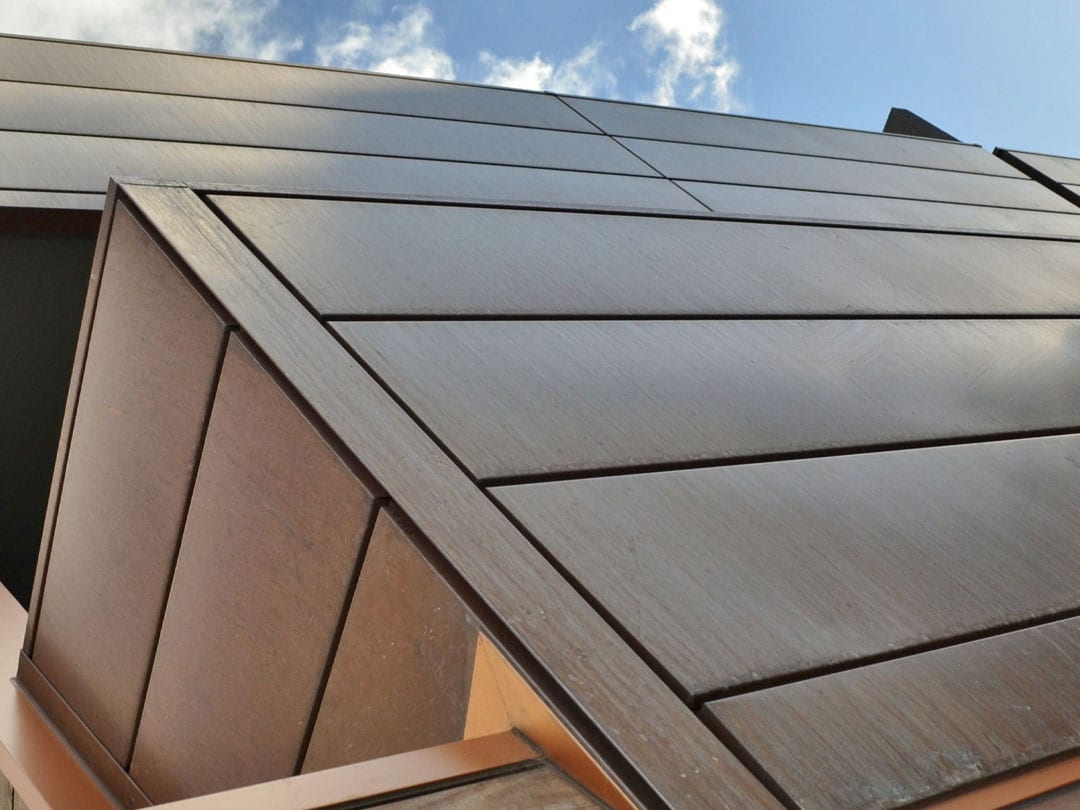

There are two main things to consider when talking about different choices of metal roofing—the style of roof and the material used. The style of the roof determines the profile of the panels or tiles used. The most expensive option is a standing seam roof, which is also generally considered to be the better looking of the metal roofing options (taste is subjective, of course).

There are also corrugated roofing panels, which feature a series of troughs and peaks that create additional strength and direct the flow of rainwater. Finally, there are metal tiles, which look like regular roof tiles but are made from metal.

Where things can get a little more complicated is with the material used to make those tiles or panels.

Copper Roof

Copper is perhaps the longest-lasting of the metal roofing options in terms of resistance to the general wear and tear you would expect a roof to face. It is also quite soft, which makes it easier to work and thus better suited for uncommonly shaped rooftops. This softness also translates to a quieter experience during things like rain, since the metal absorbs the impact more readily than a harder material.

The main disadvantages of copper as a roofing material are its reaction to temperature swings and the cost. Copper expands and contracts with temperature changes more so than other roofing materials, which means the construction of the roof needs careful planning to compensate for this movement. It is also more expensive than different types of roofing. As with most things in life, you get what you pay for—copper roofing is costly for a reason.

Aluminium Roofing

Though it is not technically correct to say that aluminium doesn’t react to its environment, it is one of the most resistant to corrosion of the common metal roofing options. The truth is it reacts almost immediately, to the air around it, and that surface reaction protects the rest of the metal from further corrosion. It for this reason that aluminium is favoured when choosing metal roofing for coastal properties, where salt corrosion is a real problem.

Like copper, aluminium is more costly than most of its counterparts. This can lead to thinner panels being used in order to bring costs down, which in turn results in roofing that is more susceptible to damage from things like wind.

Zinc Roofing

Zinc is typically favoured for commercial products and has perhaps the longest life expectancy of the roofing metals to choose from. It also has a lower melting point than the alternatives, which means it requires less energy to make a panel of zinc roofing material, which in turns makes it better for the environment.

The main downside to zinc is its tendency to “chalk” over if not painted. This means developing a powdery white patina over time. This can be cleaned to a degree, but the best option is usually to paint it before it has a chance to chalk over.

Steel Roofing

By far the most common metal used for metal roofing solutions, steel can come in a variety of flavours, each utilising a different method to protect the metal from corrosion. Galvanised steel sports a coating of zinc, whereas weathering steel is designed to allow the outer layer to rust, protecting the inner layers. Galvalume steel is similar to galvanised steel with the exception that it uses aluminium rather than zinc.

The primary advantage of steel roofing over the alternatives is the lower costs and flexibility of use. It is for these reasons that steel has become by far the most commonly used metal for roofing.

As a slight aside, steel roofing is also sometimes referred to as “tin”, however, this just a bit of a hangover from times gone by. Real tin roofing has not been commonly used in over half a century.

Which Metal Roof is Best?

The best metal roof for your property will often come down to individual circumstances. For example, copper roofing may be the best option for your building, but if you can’t afford copper roofing, it is by default, not the best option.

One of the main things to consider when choosing your metal roofing solution is the environment. Are you in a location that gets a lot of wind, meaning you will need a more substantial roofing solution?

Do you get a lot of rain, suggesting that a softer material would be better so as to not drive you insane with the continual din that rain on a loud metal roof would cause? What about proximity to the coast? Salt corrosion is particularly effective on steel.

If you were to choose one “money is no object” metal roofing solution regardless of the circumstances, a standing seam copper or zinc roof would probably be your best bet. However, we would advise you to consider all the factors and pick something suited specifically to your situation.

Are Metal Roofs More Expensive Than Tile Roofs?

If you are looking at the upfront costs alone, there are very few situations where a metal roof will be more expensive than a tile roof. You only have to consider what is involved to see why this would be the case. For example, a tiled roof—depending on the size—may use thousands of tiles, with each one needing to be carefully positioned and secured in place.

Metal roofing panels also need to be secured in place, of course, but they cover a much larger area, and the time spent covering a certain amount of space with metal roofing panels will be much less than the equivalent space in tiles.

The next thing to consider is the process of getting around on the roof as it is being worked on. Metal roofs are usually built to withstand enough force that you can walk on them, making maneuvering around the roof as it is being worked on relatively easy. Tiled roofs can also be walked on, but they required substantially more care to avoid damaging the tiles that have already been laid.

All of this factors into the labour side of things—it will typically cost less to have someone install a metal roof in terms of the labour they charge—but there are areas where savings could be made over a tiled roof in the materials themselves. That is, the materials other than the tiles or metal panels themselves. For example, metal roof panels often work out cheaper than the equivalent amount of tiles (of course, this depends on the tiles and roof panels being compared). It is also the case that some types of metal roofs do not need underlayment, which is not the case for tiled roofs.

It is possible to have a metal roof install that is more expensive than a tiled roof in some circumstances—and if you’re considering asphalt shingles rather than tiles, it will undoubtedly be cheaper—but generally speaking; it will be cheaper to install a metal roof in most cases. That being said, in section, we have only talked about installation costs. When pricing a job, it is important to factor in longer-term costs as well, such as maintenance and lifespan, which brings us to our next section…

Do Metal Roofs Last Longer Than Tile Roofs?

Working on the assumption that you are making far-reaching plans for your home or business premises, thinking long term is something that your future self will thank you for. In this case, we’re talking about the average lifespan of the different types of roofing.

Metal roofing has a life expectancy of around half that of the fifty years that tiled roofing is expected to last. This shortened life expectancy can be brought down further by the climate in which the roof finds itself in—more on that later.

If you are going to plan long term, you will need to factor in the costs you are likely to face in the future, and for a metal roof, that may include the cost of replacing the roof entirely somewhere down the line.

Granted, we are still talking about relatively long timescales here. Even with the reduced life expectancy of metal roofing, it should last the full term of an average mortgage. But for people looking to make a house their “forever home”, twenty-five years is still soon enough to be their problem in the long run.

Of course, we are not always in a position to front-load our financial decisions. If a roof needs to be built and the cheapest option is the only option you can afford, then that will be the best option. However, if you are having your roof rebuilt, perhaps as part of an ongoing renovation, it may be worth holding off until you can afford to get the tiled roofing, as it will last longer and may work out cheaper over the course of its life.

Can You Walk on a Metal Roof Without Damaging It?

As a general rule, metal roofing can be considered safe to walk on, though there are some caveats to this. Firstly, there are different styles of metal roof, and the best way to approach walking on your metal roof will change depending on the type you have installed.

For metal tile roofing—a style of metal roofing that resembles tiled roofing by using small metal tiles instead of large panels—it is safe to walk on, but it advised to walk on the low spots, rather than the ribs of the tile.

For corrugated panels—which are larger ribbed panels with high and low spots—it is again better to walk on the low areas only. For standing-seam metal roofing, on the other hand, it is more or less okay to step on any part of the roofing panels, since the raised areas are much smaller and closer to the deck.

The primary reason for advising you walk on the low spots is that these areas are closer to the roof decking, and so are better supported by the structure of the roof itself. The high points, on the other hand, could be compressed with enough weight, damaging the roof panel and resulting in an unsightly dent in your roof. And, in some cases, it could compromise the integrity of the roof, allowing rainwater to get in.

Another reason to avoid standing on the high points is that there is an increased chance of slipping when walking on what is essentially a much smaller surface area. It doesn’t take a roofing expert to understand that slipping while walking around on a roof can lead to severe injury, or worse.

How Often do Metal Roofs Need to be Painted?

While your roof should be inspected every year or two to ensure you catch any developing problems before they become major issues, you shouldn’t need to paint your metal roof any more often than once a decade on average.

Of course, this period can be different depending on factors like the quality of paint used, the preparation beforehand, and the quality of the painting work itself. Generally speaking, however, if the painting work is professionally done with quality paint, around a decade is a good rule of thumb between fresh coats of paint.

If you are in any doubt about whether your roof might need painting, it is best to get it inspected—especially if the roof is made from steel, which can rust if not properly looked after.

How do Metal Roofs Hold up on Beachside Residences?

Many metals—steel in particular—are susceptible to salt corrosion, which can dramatically shorten the useable life of a metal roof solution. Beachside properties are subjected to considerably more salt than inland properties due to their proximity to the saltwater ocean.

If your roof is made from copper, zinc, or aluminium, it should be fine at the beach. If, however, your roof is made from one of the steel options, you will need to keep a close eye on it, and painting should be considered a must to protect your roof further.

Do Metal Roofs Attract Lightning?

A metal roof in and of itself will not attract lightning. Despite the conductivity of metal—especially when compared to something like wood, or concrete—it is simply not the way lightning works.

Lightning is just electricity, and electricity seeks the path of least resistance, which is why taller objects get hit with lightning first—they are closer to the clouds that the lightning originated from. For this reason, your building may get struck by lightning, but it will not be because of the metal roof.

Interestingly, a metal roof may reduce the damage that the lightning causes if it does strike your building. The explosions and fires you see when lightning hits something like a tree are the result of resistance due to the material not being a good conductor of electricity. If your building has a metal roof and there is a metal substructure, the lightning has a much easier path to ground.

Is Underlayment Necessary for a Metal Roof?

If we were pushed on the word “necessary”, we would probably say no. Underlayment is not necessary for metal roofing. However, we would suggest it is worth investing in regardless. Underlayment helps with a variety of things, such as temperature regulation and noise dampening.

It is also worth considering what your property is to be used for. If you are roofing a workshop, it is probably fine to skip the underlayment. For a residential property, on the other hand, we would recommend taking that extra step, even if you don’t need to.

Is Corrugated Metal Roofing Better Than Flat Profile Roofing?

Which of these styles is better is largely a subjective decision. Standing seam roofing tends to look a little cleaner, and more modern, whereas corrugated roofing tends to handle heavy weather a little better.

That being said, corrugated roofing can also look great when used correctly, and standing seam roofing handles bad weather just fine when not being compared to corrugated. If in doubt, it’s worth speaking to a specialist about your options, but you are probably fine just choosing the one you like the look of the most.

Final Thoughts

Ultimately, metal roofing offers many of the same advantages of any other kind of roofing; it is just a matter of choosing the style and material that best suits your situation.

Granted, it is unlikely that a metal roof will last as long as a tiled alternative, but with proper care and attention, you should be able to get many decades of safe use out of your metal roof before it needs replacing entirely.

1 Roof Vent

Supply & Installation Price

$520/1

1 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

2 Roof Vent

Supply & Installation Price

$860/2

2 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

3 Roof Vent

Supply & Installation Price

$1,090/3

3 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

4 Roof Vent

Supply & Installation Price

$1,300/4

4 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price