Why Has My Roof Turbine Vent Stopped Spinning?

Whirlybird Roof Vent Installation Packages for Greater Sydney – Click Here >

Gutter Sumps to the Trade Shipped Free Australia-Wide – Click Here >

Rain Heads to the Trade Shipped Free Australia-Wide – Click Here >

Dambuster Rain Heads Shipped Free Australia-Wide – Click Here >

Eco-Friendly Roofing Insulation Shipped Free – Click Here >

My Whirlybird Roof Vent is Not Spinning?

Roof turbine vents are a common sight atop many homes and commercial buildings. These simple yet effective devices play a crucial role in maintaining proper ventilation within a structure. By harnessing the power of wind, they help expel hot and stale air from the attic space while promoting air circulation. However, like any mechanical component, roof turbine vents can sometimes stop spinning, leaving homeowners and property managers wondering why. In this article, we will explore the various reasons why your roof turbine vent may have come to a halt and what you can do to address the issue.

Understanding Roof Turbine Vents

Before delving into the reasons behind a non-spinning roof turbine vent, let’s briefly understand how these devices work. Roof turbine vents, also known as whirlybird vents or attic fans, consist of a cylindrical body with a series of vanes or fins extending outward from the top. These vanes capture wind energy and convert it into rotational motion. As the vent spins, it draws air out of the attic space, helping to regulate temperature and moisture levels.

Reasons for a Non-Spinning Roof Turbine Vent

- Lack of Sufficient Wind

One of the most common reasons for a non-spinning roof turbine vent is a lack of sufficient wind. These vents rely on natural wind currents to create the rotational force needed to expel air from the attic. If your location experiences periods of calm or low wind, the vent may not spin as frequently or at all. This is particularly common in urban areas with tall buildings and obstructions that can disrupt airflow.

Solution: Unfortunately, there’s not much you can do to change the wind patterns in your area. You might consider alternative ventilation options, such as electric attic fans, which can operate independently of wind conditions.

- Obstructions and Debris

Roof turbine vents are susceptible to debris accumulation and obstructions. Leaves, twigs, bird nests, or other debris can get lodged in the vent, preventing it from spinning freely. In some cases, ice and snow buildup during the winter months can also hinder the vent’s movement.

Solution: Regular maintenance is essential to ensure your roof turbine vent remains functional. Periodically inspect and clean the vent to remove any obstructions. If you live in a region prone to snow and ice, consider installing a vent cover or heat tape to prevent ice buildup.

- Mechanical Wear and Tear

Over time, the mechanical components of a roof turbine vent can wear down due to exposure to the elements, including sunlight, rain, and temperature fluctuations. Bearings and lubrication can deteriorate, leading to increased friction and reduced spinning ability.

Solution: If you suspect mechanical wear and tear is the issue, you may need to replace the vent or its internal components. Consult a professional to assess the condition of your vent and determine the appropriate course of action.

- Age and Corrosion

Age-related corrosion can also affect the performance of a roof turbine vent. The vent’s metal components may rust or deteriorate, hindering its ability to spin smoothly.

Solution: In cases of severe corrosion or rust, replacing the vent is often the best solution. Regularly painting or coating the vent can help prolong its lifespan and prevent corrosion.

- Imbalanced Blades

An imbalanced blade assembly can cause the roof turbine vent to wobble or stop spinning altogether. This imbalance can occur due to damage or deformities in the blades or uneven accumulation of debris.

Solution: Carefully inspect the blades for damage or debris. If you notice any issues, it’s best to replace the blades or the entire vent to ensure proper balance and functionality.

- Roofing Material Interference

In some cases, the roofing material itself may interfere with the vent’s operation. If the roof was installed or repaired incorrectly, it could obstruct the vent’s ability to spin freely.

Solution: Consult a roofing professional to assess the roof’s condition and make any necessary adjustments to ensure it doesn’t interfere with the vent’s operation.

Conclusion

A non-spinning roof turbine vent can be a source of concern for homeowners and property managers, as it can disrupt proper attic ventilation. Understanding the potential causes, from lack of wind to mechanical issues, is the first step in addressing the problem. Regular maintenance, periodic inspections, and, if necessary, professional assistance can help ensure that your roof turbine vent operates efficiently, promoting a healthier and more comfortable living environment while extending its lifespan.

Turbine vents are exhaust vents that draw out hot and humid air from inside the roof or attic. The structure of the turbine vents is such that when the wind hits, it turns and spins. But it is not meant to spin on the thrust of outside wind. It is meant to spin by the force of the hot air inside the roof that tends to go up.

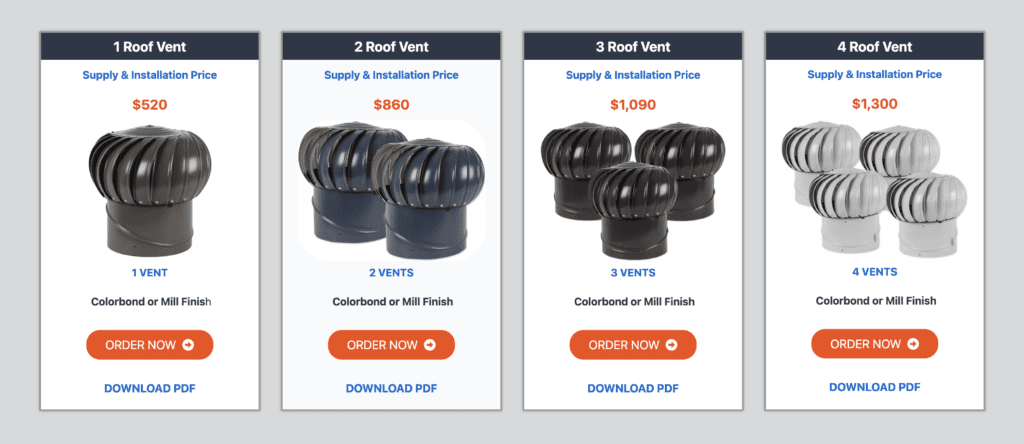

1 Roof Vent

Supply & Installation Price

$520/1

1 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

2 Roof Vent

Supply & Installation Price

$860/2

2 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

3 Roof Vent

Supply & Installation Price

$1,090/3

3 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

4 Roof Vent

Supply & Installation Price

$1,300/4

4 Ampelite 300 Spinaway

Colorbond or Mill Finish Supply & Installation Price

Download PDF

The spinning of turbine vents makes its fins to open up and that facilitates the hot air inside the roof to escape through the vent. It acts like a suction machine that sucks out hot air.

A continuous spinning of turbine vents ensures that the hot air does not get accumulated inside the attic of the building. This helps maintain a comfortable temperature inside the home or an industrial unit without spending on home cooling systems such as ACs.

Typically, turbine vents require very little maintenance. But like all machines, it can develop snags and may require a thorough checking. There is a possibility of a water leak from the point where it is attached to the roof.

But in most cases, you may not need to replace it. In normal circumstances, turbine vents will spin at the slightest wind. When it spins, the gust of hot air from inside the roof and through the fin openings is so strong that it can blow away even raindrops.

However, if you find your roof turbine vent stopped spinning, there could be some minor reasons for this. The two very common reasons are rusted — vents and obstructions not letting the vents to spin. If the vents are rusted, they need to be replaced because they would tend to stick and not spin, and obstructions such as dust, ice, leaves, etc., need to be removed.

If these two are not the reasons for your roof turbine vents to stop spinning, there could be one of the following reasons, which are only marginally more serious.

Loose Connections

The connection of the turbine vents to the standpipe may have become loose. This will allow water to penetrate the standpipe and the roofing structure. Take a good look and examine if the turbine is not properly secured with the standpipe. You can use new rust-resistant screws and nails to secure the two together. You should also seal the heads of the screws and nails with roofing cement or silicone caulk.

Ultimate Dog Training System >

Unsealed Joints

When the turbine vents are installed and fixed to the standpipe, many points need to be sealed to make sure water does not make its way through it inside the roof. If the water can pass through the vent, it will cause rusting at different places inside the vent and make it difficult to spin smoothly. So, all these points should be sealed with silicone caulk or roofing cement. You can do it afresh if there are signs of these wearing out.

Faulty Flashing

There may be a water leak near the vent’s base. In this case, the turbine vent may look like it is in good condition and has no fins missing. Chances are there is a leak around the flashing and that allows the rainwater to get inside. Undo the flashing, check for any deformity or corrosion and if it is just alright reattach with all joints and edge securely sealed with caulk or roofing cement. In case the corrosion has made holes in the metal sheet, it’s time you replaced the complete.

Turbines vents are important for attic and roof ventilation. If the roof is improperly ventilated, its surfaces can develop mold and mildew. It can also witness ice buildup and water leaks in winter. During summer, it will take a higher degree of cooling to maintain a comfortable temperature inside the living space. If turbines are not spinning, the ventilation system loses its effectiveness.

However, you can fix the problem in some simple steps. Here they are:

· Climb up and take a good look at the turbine vents from the inside. The vents may have obstructions such as insulation or boxes or some other material. The blockage will prevent the heat from escaping through the vents and that may be a reason why the vents are not spinning. If you clear the blockage by removing the debris, the vents may allow heat to pass through it, making the turbine to spin.

· Take a close look at the turbine from outside by climbing up the roof. It is possible that the bearings have become rusty or there is a broken piece. Replace the broken piece, and treat the bearings with spray solvent that clears the rust and frees the bearings. You can treat the pivot with WD-40 spray.

· There could be a blockage in the bearings’ path with materials such as ice, debris, twigs, or leaves. Free up the turbine from these blockages.

· Have a look at the entire turbine and if you find any blockage wedged into it, remove them.

· Treat silicone lubricant on the pivot point to lubricate the turbine’s internal mechanism.

Many factors guide the efficiency and smooth functioning of a turbine. For example, it can work at its best if it is fixed at the top of the roof. This ensures that it gets wind’s push from all directions.

Another important thing to remember is that the turbine vent is engineered to let out hot air. If there is no difference between inside and outside temperatures, the turbine vents do not need to work or may not work. The occasional breeze may make it spin but in reality, it is not working.

Final thoughts

Turbine vents are a very useful mechanism to maintain the temperature inside the building. It does the work exiting hot air through a vent built in the roof. The passing of hot air is prompted by the spinning of the turbine that acts like a suction machine drawing out hot air. The turbine has thin fins that block the passage of air when the turbine is not spinning. So, for the hot air to escape the building, the turbines must spin.

However, at times the turbine may not spin and there could be a reason for it. Mostly, it is a simple machine that’s easy to maintain and repair. This guide should help you solve whatever small problem you may be having with your turbine vents.